- View Mobile Number

JAPAN@INNOVICTECHNOLOGY.COM

| Business Type | Manufacturer, Exporter, Supplier |

| Brand | Innovic |

| Driven Type | Electric |

| Shape | Round |

| Click to view more | |

Product Details

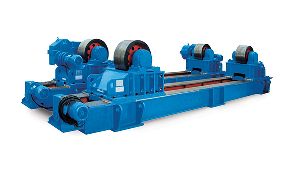

Rotary Turntables: High-Precision Solutions for Workpiece Positioning

Rotary turntables are essential tools for precise positioning of workpieces in the flat or horizontal position. They offer a cost-effective and efficient method for rotating components around a vertical axis, making them ideal for a variety of welding, assembly, and inspection applications. These turntables provide smooth, controlled movement, enhancing the accuracy and quality of operations.

Key Features of INNOVIC Rotary Turntables:

- High-Precision Rotation: Designed for precise control, these turntables ensure accurate positioning of the workpiece, allowing for uniform welding, cutting, or assembly processes.

- Versatile Applications: Suitable for a wide range of industries, including fabrication, machining, and inspection tasks. Perfect for welding circular or symmetrical components where consistent rotation is required.

- Variable Speed Control: Equipped with adjustable speed settings, operators can tailor the rotation speed to suit specific job requirements, ensuring optimal performance for both high and low-speed operations.

- Heavy-Duty Construction: Built with a robust, all-steel fabrication, these rotary turntables are engineered to handle heavy loads while maintaining stability and accuracy during rotation.

- Compact and Ergonomic Design: The compact design allows easy integration into any workshop or production environment, while providing ergonomic benefits for the operator.

- 360° Rotation with Smooth Operation: Ensures smooth and continuous 360° rotation, ideal for welding, inspection, or machining tasks that require uninterrupted movement.

- Table Locking System: Integrated with a locking mechanism to secure the table in any position, offering added stability for detailed work or when repositioning is needed.

Technical Advantages of INNOVIC Rotary Turntables:

- High Load Capacity: These rotary turntables can support heavy workpieces, ensuring versatility for applications ranging from light-duty tasks to handling large, bulky components.

- AC Motor with Variable Frequency Drive (VFD): The turntables are equipped with an AC motor and a VFD system for precise control of rotation speed, enhancing performance for both fast and slow operations, such as cladding, welding, or detailed assembly.

- Precision Bearings: The use of high-precision bearings ensures minimal friction and wear, providing long-lasting, reliable performance with minimal maintenance.

- T-Slot and Mounting Configurations: The turntable features T-slots and customizable mounting configurations for quick and secure attachment of various workpieces, making it adaptable for a wide range of applications.

- Integrated Safety Features: Designed with built-in safety mechanisms, including overload protection and emergency stop controls, ensuring safe operation even in demanding production environments.

Enhanced Productivity for Welding and Fabrication:

Rotary turntables are particularly advantageous for industries that require precise, repeatable positioning of workpieces, such as circular welding, plasma cutting, and inspection processes. Their ability to rotate components in a stable, controlled manner reduces operator fatigue and enhances production efficiency, leading to higher output quality and fewer errors.