- View Mobile Number

JAPAN@INNOVICTECHNOLOGY.COM

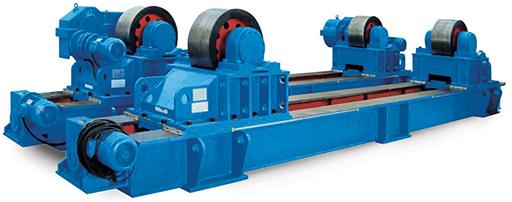

Conventional Welding Rotators

Leading Manufacturers, Exporters, Wholesaler of 100MT Conventional Welding Rotator, 10MT Conventional Welding Rotator, 20mt Conventional Welding Rotator, 300MT Conventional Welding Rotator, 30MT Conventional Welding Rotator, 50MT Conventional Welding Rotator, 60MT Conventional Welding Rotator and 75MT Conventional Welding Rotator from Anand.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Innovic |

| Driven Type | Electric |

| Color | Blue |

| Condition | New |

| Application | Industrial |

| Feature | Easy To Operate, Robust Construction |

| Country of Origin | India |

| Finishing | Painted |

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types:

Conventional Rotators

Conventional rotators consist of two sets of adjustable rollers. The rollers can be adjusted manually or through a lead-screw and ratchet mechanism to accommodate different vessel diameters. This allows for smooth transitions between varying sizes without much hassle.

Conventional Rotators: Built for Heavy-Duty Applications

- INNOVIC’s conventional rotators are engineered with capacities ranging from 1 tonne to 2000 tonnes. The frame features a robust, fabricated design that is precision-machined both on the top and underneath to ensure perfect alignment. Both the drive and idler frames come equipped with durable, fabricated and machined wheel brackets that securely support the axles and bearings of the rollers.

- Depending on the capacity, the rotators are fitted with either all-polyurethane wheels with overload protection or all-steel wheels to handle different load requirements.

- The chassis, or base structure, of the rotator is carefully designed and fabricated to support the weight of the vessel or job, with an additional margin for shock loads. This is crucial for preventing any frame distortion that could lead to misalignment of the rollers. The drive section experiences the highest strain during the loading process, as it is difficult for a crane operator to perfectly position the vessel so it contacts both roller sets simultaneously.

- If the workpiece contacts one set of rollers before the others, the initial roller experiences a full shock load, which places significant force on the drive system. To counter this, INNOVIC rotators are designed with a substantial overload margin to absorb these shock loads effectively, ensuring safe and smooth operation.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Innovic |

| Driven Type | Electric |

| Condition | New |

| Application | Industrial |

| Feature | Easy To Operate, Long Life, Low Maintenance, Robust Construction |

| Voltage | 220-380V |

| Country of Origin | India |

| Finishing | Painted |

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types:

Conventional Rotators

Conventional rotators consist of two sets of adjustable rollers. The rollers can be adjusted manually or through a lead-screw and ratchet mechanism to accommodate different vessel diameters. This allows for smooth transitions between varying sizes without much hassle.

Conventional Rotators: Built for Heavy-Duty Applications

- INNOVIC’s conventional rotators are engineered with capacities ranging from 1 tonne to 2000 tonnes. The frame features a robust, fabricated design that is precision-machined both on the top and underneath to ensure perfect alignment. Both the drive and idler frames come equipped with durable, fabricated and machined wheel brackets that securely support the axles and bearings of the rollers.

- Depending on the capacity, the rotators are fitted with either all-polyurethane wheels with overload protection or all-steel wheels to handle different load requirements.

- The chassis, or base structure, of the rotator is carefully designed and fabricated to support the weight of the vessel or job, with an additional margin for shock loads. This is crucial for preventing any frame distortion that could lead to misalignment of the rollers. The drive section experiences the highest strain during the loading process, as it is difficult for a crane operator to perfectly position the vessel so it contacts both roller sets simultaneously.

- If the workpiece contacts one set of rollers before the others, the initial roller experiences a full shock load, which places significant force on the drive system. To counter this, INNOVIC rotators are designed with a substantial overload margin to absorb these shock loads effectively, ensuring safe and smooth operation.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Innovic |

| Driven Type | Electric |

| Color | Blue |

| Condition | New |

| Feature | Low Maintenance, Robust Construction |

| Voltage | 220-380V |

| Warranty | 1year |

| Country of Origin | India |

| Delivery Time | 3-4 Weeks |

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types:

Conventional Rotators

Conventional rotators consist of two sets of adjustable rollers. The rollers can be adjusted manually or through a lead-screw and ratchet mechanism to accommodate different vessel diameters. This allows for smooth transitions between varying sizes without much hassle.

Conventional Rotators: Built for Heavy-Duty Applications

- INNOVIC’s conventional rotators are engineered with capacities ranging from 1 tonne to 2000 tonnes. The frame features a robust, fabricated design that is precision-machined both on the top and underneath to ensure perfect alignment. Both the drive and idler frames come equipped with durable, fabricated and machined wheel brackets that securely support the axles and bearings of the rollers.

- Depending on the capacity, the rotators are fitted with either all-polyurethane wheels with overload protection or all-steel wheels to handle different load requirements.

- The chassis, or base structure, of the rotator is carefully designed and fabricated to support the weight of the vessel or job, with an additional margin for shock loads. This is crucial for preventing any frame distortion that could lead to misalignment of the rollers. The drive section experiences the highest strain during the loading process, as it is difficult for a crane operator to perfectly position the vessel so it contacts both roller sets simultaneously.

- If the workpiece contacts one set of rollers before the others, the initial roller experiences a full shock load, which places significant force on the drive system. To counter this, INNOVIC rotators are designed with a substantial overload margin to absorb these shock loads effectively, ensuring safe and smooth operation.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Innovic |

| Driven Type | Electric |

| Condition | New |

| Feature | Easy To Operate, Low Maintenance, Robust Construction |

| Voltage | 3800-440V |

| Warranty | 1year |

| Country of Origin | India |

| Finishing | Painted |

| Payment Terms | L/C |

| Delivery Time | 6-7 Weeks |

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types:

Conventional Rotators

Conventional rotators consist of two sets of adjustable rollers. The rollers can be adjusted manually or through a lead-screw and ratchet mechanism to accommodate different vessel diameters. This allows for smooth transitions between varying sizes without much hassle.

Conventional Rotators: Built for Heavy-Duty Applications

- INNOVIC’s conventional rotators are engineered with capacities ranging from 1 tonne to 2000 tonnes. The frame features a robust, fabricated design that is precision-machined both on the top and underneath to ensure perfect alignment. Both the drive and idler frames come equipped with durable, fabricated and machined wheel brackets that securely support the axles and bearings of the rollers.

- Depending on the capacity, the rotators are fitted with either all-polyurethane wheels with overload protection or all-steel wheels to handle different load requirements.

- The chassis, or base structure, of the rotator is carefully designed and fabricated to support the weight of the vessel or job, with an additional margin for shock loads. This is crucial for preventing any frame distortion that could lead to misalignment of the rollers. The drive section experiences the highest strain during the loading process, as it is difficult for a crane operator to perfectly position the vessel so it contacts both roller sets simultaneously.

- If the workpiece contacts one set of rollers before the others, the initial roller experiences a full shock load, which places significant force on the drive system. To counter this, INNOVIC rotators are designed with a substantial overload margin to absorb these shock loads effectively, ensuring safe and smooth operation.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Driven Type | Electric |

| Color | Yellow |

| Condition | New |

| Automation Grade | Semi-Automatic |

| Application | Industrial |

| Feature | Easy To Operate, Robust Construction |

| Voltage | 230-380V |

| Country of Origin | India |

| Brand Name | Innovic |

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types:

Conventional Rotators

Conventional rotators consist of two sets of adjustable rollers. The rollers can be adjusted manually or through a lead-screw and ratchet mechanism to accommodate different vessel diameters. This allows for smooth transitions between varying sizes without much hassle.

Conventional Rotators: Built for Heavy-Duty Applications

- INNOVIC’s conventional rotators are engineered with capacities ranging from 1 tonne to 2000 tonnes. The frame features a robust, fabricated design that is precision-machined both on the top and underneath to ensure perfect alignment. Both the drive and idler frames come equipped with durable, fabricated and machined wheel brackets that securely support the axles and bearings of the rollers.

- Depending on the capacity, the rotators are fitted with either all-polyurethane wheels with overload protection or all-steel wheels to handle different load requirements.

- The chassis, or base structure, of the rotator is carefully designed and fabricated to support the weight of the vessel or job, with an additional margin for shock loads. This is crucial for preventing any frame distortion that could lead to misalignment of the rollers. The drive section experiences the highest strain during the loading process, as it is difficult for a crane operator to perfectly position the vessel so it contacts both roller sets simultaneously.

- If the workpiece contacts one set of rollers before the others, the initial roller experiences a full shock load, which places significant force on the drive system. To counter this, INNOVIC rotators are designed with a substantial overload margin to absorb these shock loads effectively, ensuring safe and smooth operation.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Driven Type | Electric |

| Color | Blue |

| Condition | New |

| Application | Industrial |

| Feature | Easy To Operate, Low Maintenance, Robust Construction |

| Voltage | 230 V-380V |

| Country of Origin | India |

| Finishing | Powder Coated |

| Brand Name | Innovic |

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types:

Conventional Rotators

Conventional rotators consist of two sets of adjustable rollers. The rollers can be adjusted manually or through a lead-screw and ratchet mechanism to accommodate different vessel diameters. This allows for smooth transitions between varying sizes without much hassle.

Conventional Rotators: Built for Heavy-Duty Applications

- INNOVIC’s conventional rotators are engineered with capacities ranging from 1 tonne to 2000 tonnes. The frame features a robust, fabricated design that is precision-machined both on the top and underneath to ensure perfect alignment. Both the drive and idler frames come equipped with durable, fabricated and machined wheel brackets that securely support the axles and bearings of the rollers.

- Depending on the capacity, the rotators are fitted with either all-polyurethane wheels with overload protection or all-steel wheels to handle different load requirements.

- The chassis, or base structure, of the rotator is carefully designed and fabricated to support the weight of the vessel or job, with an additional margin for shock loads. This is crucial for preventing any frame distortion that could lead to misalignment of the rollers. The drive section experiences the highest strain during the loading process, as it is difficult for a crane operator to perfectly position the vessel so it contacts both roller sets simultaneously.

- If the workpiece contacts one set of rollers before the others, the initial roller experiences a full shock load, which places significant force on the drive system. To counter this, INNOVIC rotators are designed with a substantial overload margin to absorb these shock loads effectively, ensuring safe and smooth operation.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Color | Yellow |

| Condition | New |

| Application | Industrial |

| Feature | Easy To Operate, Robust Construction |

| Voltage | 230-380V |

| Country of Origin | India |

| Brand Name | Innovic |

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types:

Conventional Rotators

Conventional rotators consist of two sets of adjustable rollers. The rollers can be adjusted manually or through a lead-screw and ratchet mechanism to accommodate different vessel diameters. This allows for smooth transitions between varying sizes without much hassle.

Conventional Rotators: Built for Heavy-Duty Applications

- INNOVIC’s conventional rotators are engineered with capacities ranging from 1 tonne to 2000 tonnes. The frame features a robust, fabricated design that is precision-machined both on the top and underneath to ensure perfect alignment. Both the drive and idler frames come equipped with durable, fabricated and machined wheel brackets that securely support the axles and bearings of the rollers.

- Depending on the capacity, the rotators are fitted with either all-polyurethane wheels with overload protection or all-steel wheels to handle different load requirements.

- The chassis, or base structure, of the rotator is carefully designed and fabricated to support the weight of the vessel or job, with an additional margin for shock loads. This is crucial for preventing any frame distortion that could lead to misalignment of the rollers. The drive section experiences the highest strain during the loading process, as it is difficult for a crane operator to perfectly position the vessel so it contacts both roller sets simultaneously.

- If the workpiece contacts one set of rollers before the others, the initial roller experiences a full shock load, which places significant force on the drive system. To counter this, INNOVIC rotators are designed with a substantial overload margin to absorb these shock loads effectively, ensuring safe and smooth operation.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Innovic |

| Driven Type | Electric |

| Color | Blue |

| Condition | New |

| Feature | Easy To Operate, Robust Construction |

| Voltage | 230-380V |

| Country of Origin | India |

| Finishing | Painted |

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types:

Conventional Rotators

Conventional rotators consist of two sets of adjustable rollers. The rollers can be adjusted manually or through a lead-screw and ratchet mechanism to accommodate different vessel diameters. This allows for smooth transitions between varying sizes without much hassle.

Conventional Rotators: Built for Heavy-Duty Applications

- INNOVIC’s conventional rotators are engineered with capacities ranging from 1 tonne to 2000 tonnes. The frame features a robust, fabricated design that is precision-machined both on the top and underneath to ensure perfect alignment. Both the drive and idler frames come equipped with durable, fabricated and machined wheel brackets that securely support the axles and bearings of the rollers.

- Depending on the capacity, the rotators are fitted with either all-polyurethane wheels with overload protection or all-steel wheels to handle different load requirements.

- The chassis, or base structure, of the rotator is carefully designed and fabricated to support the weight of the vessel or job, with an additional margin for shock loads. This is crucial for preventing any frame distortion that could lead to misalignment of the rollers. The drive section experiences the highest strain during the loading process, as it is difficult for a crane operator to perfectly position the vessel so it contacts both roller sets simultaneously.

- If the workpiece contacts one set of rollers before the others, the initial roller experiences a full shock load, which places significant force on the drive system. To counter this, INNOVIC rotators are designed with a substantial overload margin to absorb these shock loads effectively, ensuring safe and smooth operation.